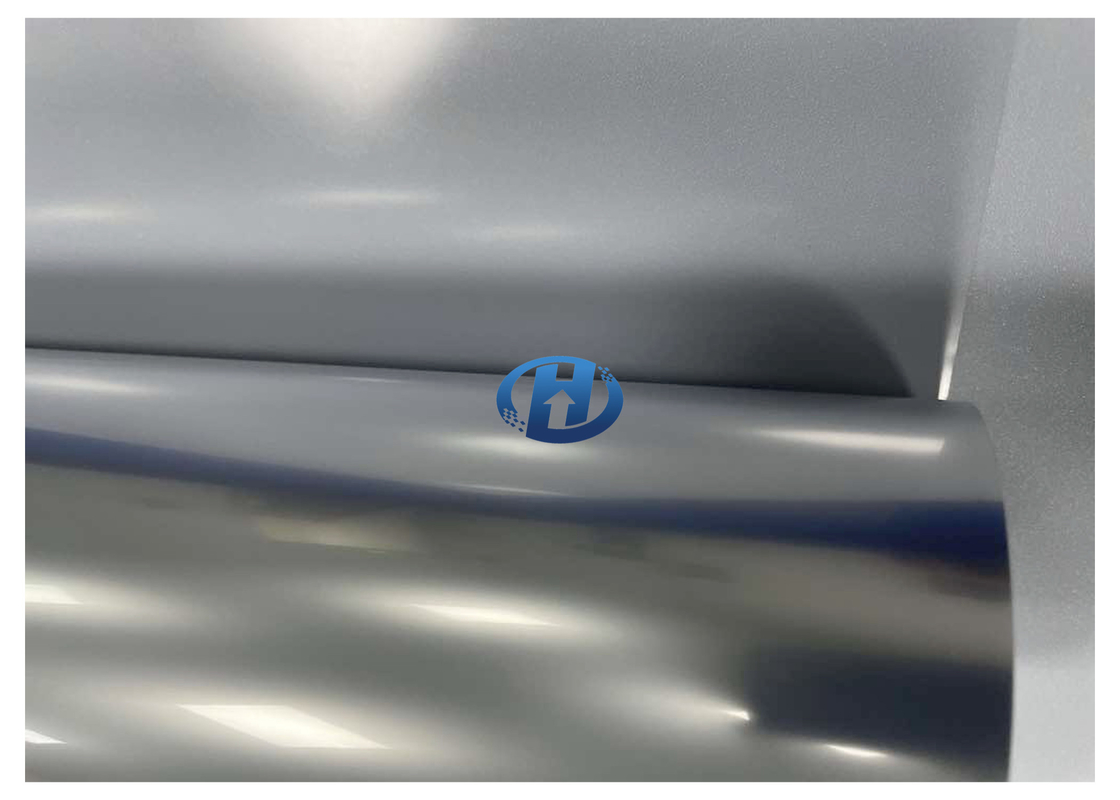

20um PET Release Film Optical Grade Film Waste Discharge Film In 3C Industry Converting Process Film

-

Highlight

20um PET Release Film

,Polyethylene Terephthalate Release Film

,UV Cured PET Release Film

-

MaterialPolyethylene Terephthalate

-

ColorClear, Customized

-

Thickness20μm ± 3%

-

Width≤2300mm

-

Core6" Or 3"

-

CoatingDouble Side UV Cured Silicone Coating

-

Release ForceSide A 1-5gf, Side B 5-10gf, The Ratio Of Release Force Can Be Customized

-

Subsequent Adhesion Rate≥75%

-

Length≤12000m

-

Splice≤1

-

SampleA4 Sheet For Free

-

Place of OriginChina

-

Brand NameHSF

-

Model Number20T0510DS-PET

-

Minimum Order Quantity1000kg

-

Packaging DetailsPE wrapping film + Bubble film + Wooden pallet (W.1100mm x L. 1100mm x H. 100mm), customized

-

Delivery Timewithin 10 days

-

Payment TermsT/T, L/C

-

Supply Ability80000kg per week

20um PET Release Film Optical Grade Film Waste Discharge Film In 3C Industry Converting Process Film

Clear 20μm PET Silicone Release Film, for converting processing, or laminating with various adhesive side, easy peel-off

| S/N | Test Item | Unit | Value | Test Method | |

| 1 | Thickness | μm | 19.46 | DIN53370 | |

| 2 | Color | - | Transparent | - | |

| 3 | Tensile Strength | MD | N/mm² | 182 | DIN53455-6-5 |

| TD | N/mm² | 216 | |||

| 4 | F-5 | MD | N/mm² | 97.8 | DIN53455-6-5 |

| TD | N/mm² | 89.4 | |||

| 5 | Elongation @ break (%) |

MD

|

% | 116 | DIN53455-6-5 |

| TD | % | 96 | |||

| 6 | Elasticity Modulus | MD | N/mm² | 3565 | DIN53455-6-5 |

| TD | N/mm² | 3840 | |||

| 7 | Friction Coefficient | F/M-US | 0.411 | DIN53375 | |

| F/M-UK | 0.315 | ||||

| 8 | Haze | % | 70.6 | ASTM D1003 | |

| 9 | Luminousness | % | 75.8 | ASTM D1003 | |

| 10 | Glossiness | % | 26.5-28 | ASTM D2457 | |

| 11 | Thermal Shrinkage | MD | % | 1.5 | ASTM D1204 150℃, 30min. |

| TD | % | 0 | |||

| 12 | Wetting Tension | mN/m | 58 | ASTM D2578 | |

| 13 | Release Force | Inner | gf/25mm | 3 | Final 10, 20min. |

| Outer | 10 | ||||

| 14 | Sub-sequent Adhesion Rate | Inner | % | 91 | |

| Outer | 89 | ||||

Widely applicable for converting processing, or laminating with acrylic base PSA side, rubber base adhesive, hot melts, inks,

cast materials and other special films, easy to peel off.

1. Packaging decoration:

PET release film can be aluminized by vacuum aluminizing machine to form a kind of aluminized cardboard with metallic luster, which is characterized by degradable and recyclable environmental attributes and is a green, novel and advanced packaging material that has just been developed.

2. Transfer:

PET transfer film can also be referred to as PET transfer film, which is characterized by its reusability. It can be used in the field of printing on the one hand, PET release film can be transferred to glass, porcelain, plastic, metal, leather and cotton textile and other material objects by heating and pressure through a special process;on the other hand, it can also be used in highly integrated chemical, plate making, vapor deposition, precision molds and molding of high-tech industries.

3. Protective film:

PET release film can also be applied to the production of PET protective film material, so it can be used not only for the protection of stainless steel, nameplates and aluminum panels, as well as laptop cases, display screen protection, can also be applied to electronic die-cutting, photoelectric die-cutting, electronics and other products in the process of protection.

4. Reflective film:

First-class PET release film can be made into PET reflective film through a special process, which has excellent optical properties, thermal stability and light aging resistance, etc. It is mainly used in reflective requirements for reflective traffic signs, billboards and industrial safety signs, etc.

![]()

![]()