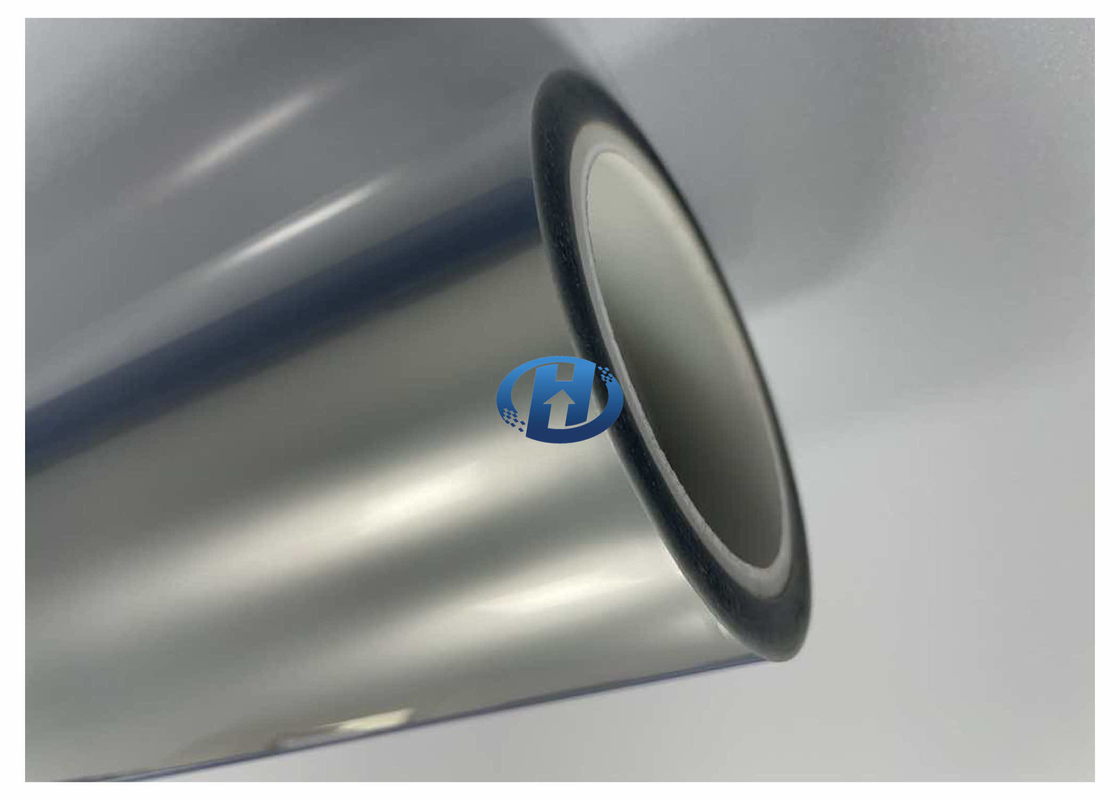

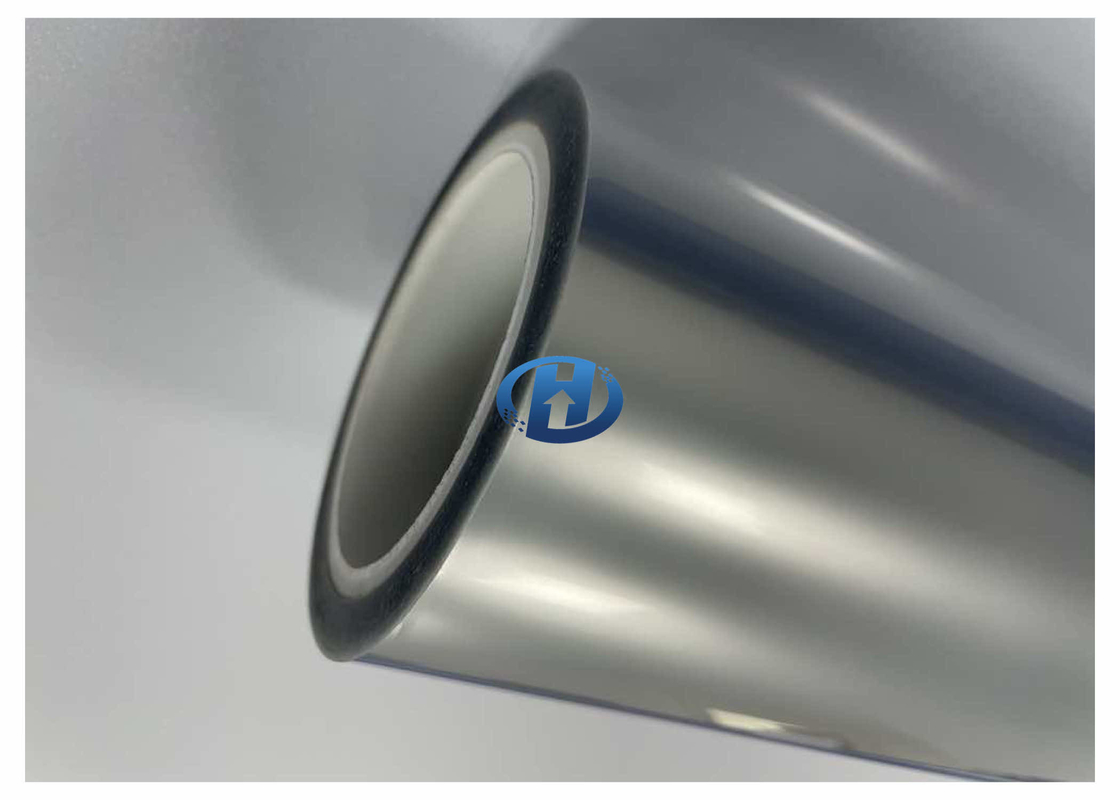

100 μm Clear PET Release Liner Solvent Resistance Mainly used as waste discharge film in 3C industries

-

Highlight

Clear Fluorosilicone Release Liner

,clear polyester film 100micron

,Fluorosilicone Release Liner 100micron

-

MaterialPolyethylene Terephthalate

-

ColorClear, Customized

-

Thickness100μm ± 6%

-

Width≤1300mm

-

Core6" Or 3"

-

CoatingSingle Side Thermal Cured Fluorine Coating

-

Release Force5-8gf, Customized

-

Subsequent Adhesion Rate≥85%

-

Length≤2000m

-

Splice≤1

-

SampleA4 Sheet For Free

-

Place of OriginChina

-

Brand NameHSF

-

Model Number100T10F-SS-PET

-

Minimum Order Quantity1000kg

-

Packaging DetailsPE wrapping film + Bubble film + Wooden pallet (W.1100mm x L. 1100mm x H. 100mm), customized

-

Delivery Timewithin 10 days

-

Payment TermsT/T, L/C

-

Supply Ability80000kg per week

100 μm Clear PET Release Liner Solvent Resistance Mainly used as waste discharge film in 3C industries

Clear PET 100micron, Fluorine Release, stable peeling force, high residual adhesion, solvent resistance, low iridescence.

| S/N | Item | Unit | Value | |

| 1 | Backing Film Type | Clear PET 100μm | ||

| 2 | Density | g/cm³ | 1.4 | |

| 3 | Thickness | μm | 25 | |

| 4 | Width | mm | 900-1300 | |

| 5 | Tensile Strength (ASTM D 882) | MD | Mpa | >200 |

| TD | >200 | |||

| 6 | Elongation @ break (ASTM D 882) | MD | % | >160 |

| TD | >110 | |||

| 7 | Heat Shrinkage (ASTM D 1204) | MD | % | <1.4 |

| TD | <0.3 | |||

| 8 | Release Force (PSTC) | gf/25mm | 5-8 | |

| 9 | Sub-sequent Adhesion Rate (PSTC) | % | ≥85 | |

Fluorine release film is made of PET as the base material and coated with fluorine release agent on one side.

It has the advantages of stable peeling force, high residual adhesion, solvent resistance, and low iridescence.

It is recommended to use this product for processing with dry or hot lamination process.

Be sure to evaluate the actual processing requirements (material/process) to confirm the suitability of this product before ordering.

High temperature/high humidity must be avoided, and more importantly, direct sunlight must be avoided.

UV light will affect the quality performance of the release film.

![]()

![]()