-

Highlight

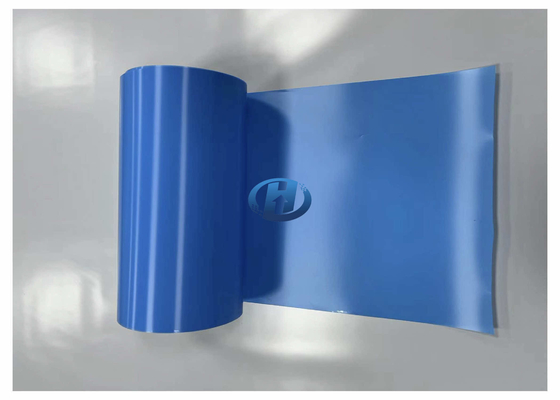

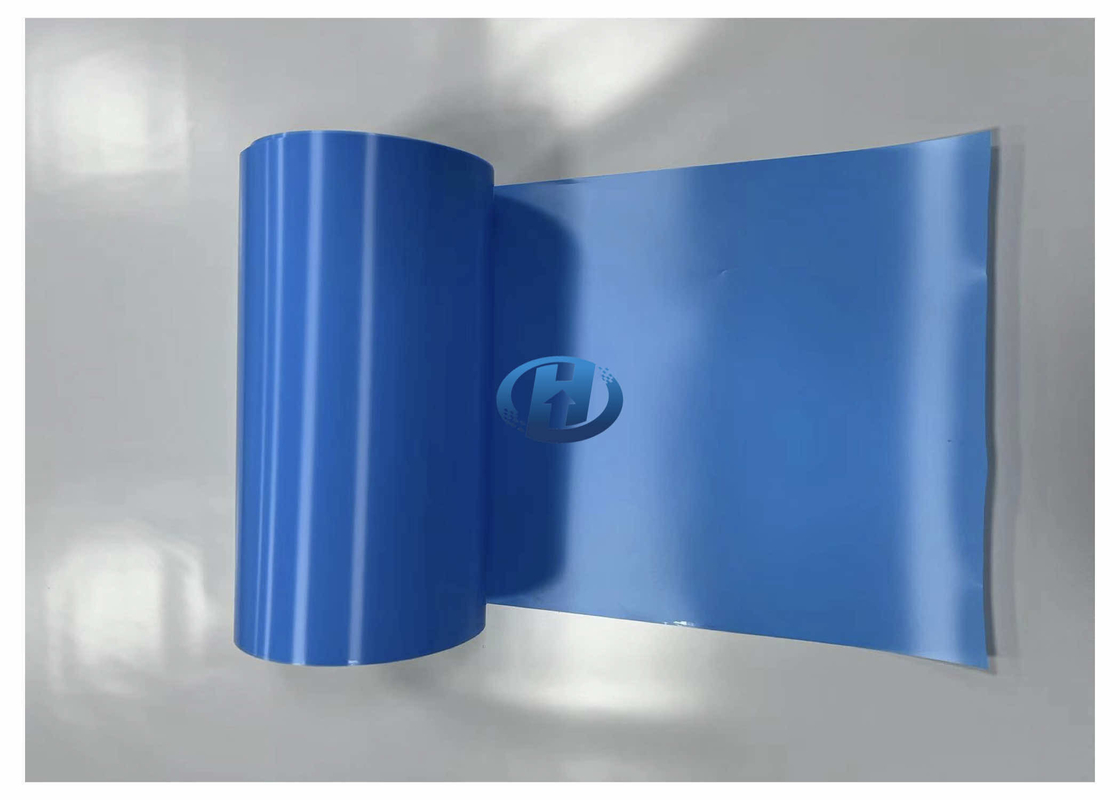

80micron MOPP Film

,Mono Axially Oriented Polypropylene Release Film

,70micron MOPP Film

-

MaterialMono-axially Oriented Polypropylene

-

ColorLight Green, Customized

-

Halogen FreeYes

-

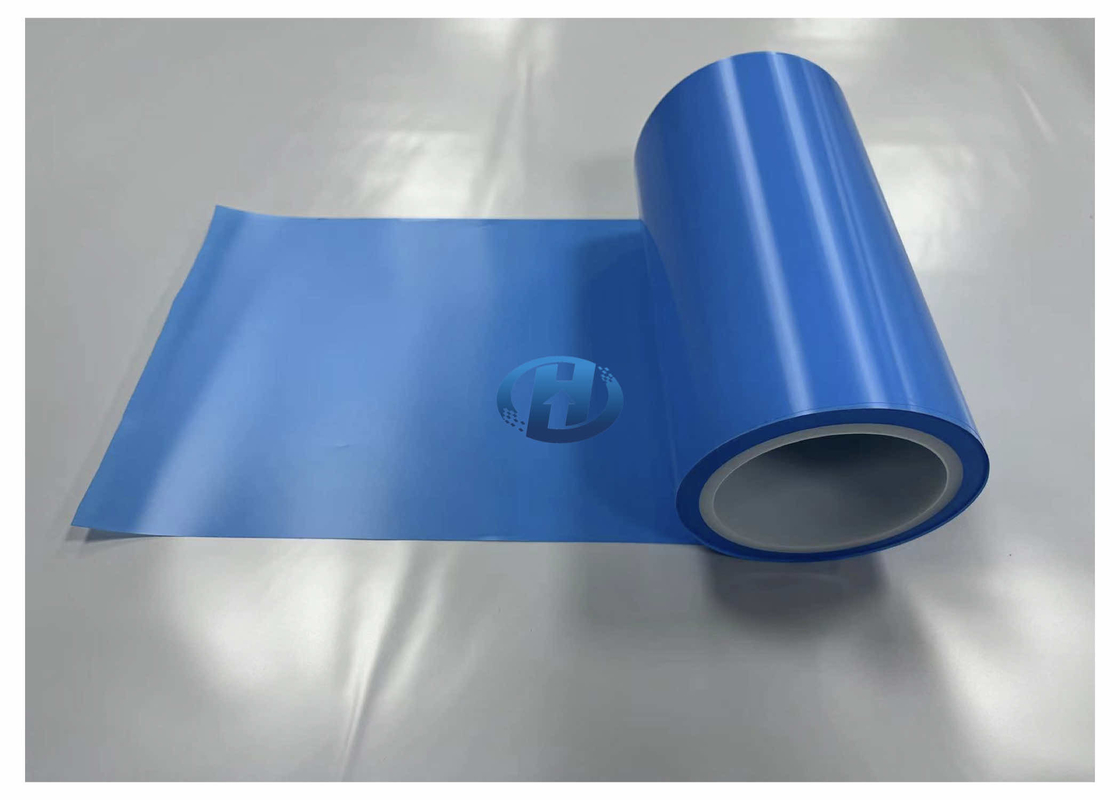

Thickness75 ± 5μm, Customized

-

Width1220 ± 5mm

-

Core3" Or 6"

-

CoatingSingle Side UV Cured Silicone Coating

-

Release Force3-5gf

-

Length3000m ± 200m, Customized

-

SampleA4 Sheet For Free

-

Place of OriginChina

-

Brand NameHSF

-

Model Number75G-SS5-MOPP

-

Minimum Order Quantity10000㎡

-

Packaging DetailsPE wrapping film + Bubble film + Wooden pallet (W.1100mm x L. 1100mm x H. 100mm), customized

-

Delivery Timewithin 10 days

-

Payment TermsT/T, L/C

-

Supply Ability80000kg per week

70 μm 80 μm MOPP Film Mono-Axially Oriented Polypropylene Release Film

Mono-axially oriented polypropylene Release Film, S, 75micron, Light green, High mechanical strength, Transparency.

| 1 | Appearance | No air bubbles / stains / breakage / impurities | Measured | |

| 2 | Size | Width (mm) | 1220 ± 5 | 1220 |

| Thickness (mm) | 0.075 ± 0.005 | 0.075 | ||

| 3 | Tensile Strength (Mpa) | MD | ≥ 280 | 325 |

| 4 | Color difference | Colorimeter △E | < 3 | ok |

| 5 | Elongation @ break (%) | TD | ≥ 500 | 621 |

| MD | ≥ 30 | 33 | ||

| 6 | Surface Tension (Corona treatment) | Dyne Value | ≥42 dyne | 46 |

| 7 | Release Force (gf/25mm 20min.Finat 10) | 3-5 | 4 | |

| 8 | Subsequent Adhesion (%) | ≥ 75 | 86 | |

| 9 | Winding direction | Customized | - | |

| 10 | Splice No. | ≤1 | - | |

| 10 | Splice No. | ≤1 | - | |

MOPP is the abbreviation of Mono-axially Oriented Polypropylene.

It has a significant high tensile strength in the mechanical direction,

the longitudinal strength and longitudinal crack resistance are greatly improved, and it has good kink.

It has the advantages of light weight, transparency, non-toxicity, moisture resistance and high mechanical strength,

and is widely used in packaging films, cigarette film pulling wires, etc., and is widely used as composite film substrate,

self-adhesive tapes, cable tapes, tear tapes, silicone-coated base films, strapping tapes (such as wrapping steel),

article labels, tire lining applications, etc.

At present, the most commonly used production method of MOPP film in the industry is the main casting method.

In the casting method, the prepared plastic is firstly plasticized and melted through an co-extruder.

It is extruded through a T-shaped structure forming die and cast in a sheet shape onto the roller surface of a smoothly

rotating cooling roller.

The film is cooled and shaped on the cooling roller, and then the product is rolled up after being pulled and trimmed.

The products produced by the casting method (flat film method) have superior performance and mature equipment.

It has high production efficiency and is suitable for mass production, and is currently widely used by enterprises.

![]()